Projects

Samuel Adams Cincinnati Brewery

Occupied Facilities. Located on a tight, downtown site, the renovation and expansion of this facility was completed in three phases. During all three phases, the facility remained occupied and there was never any interruption to operations. At peak construction, 150 tradesmen were operating on-site to complete the project on-time.

CLIENT

Boston Beer Company

LOCATION

Cincinnati, Ohio

ARCHITECT

Hixson

Project Overview

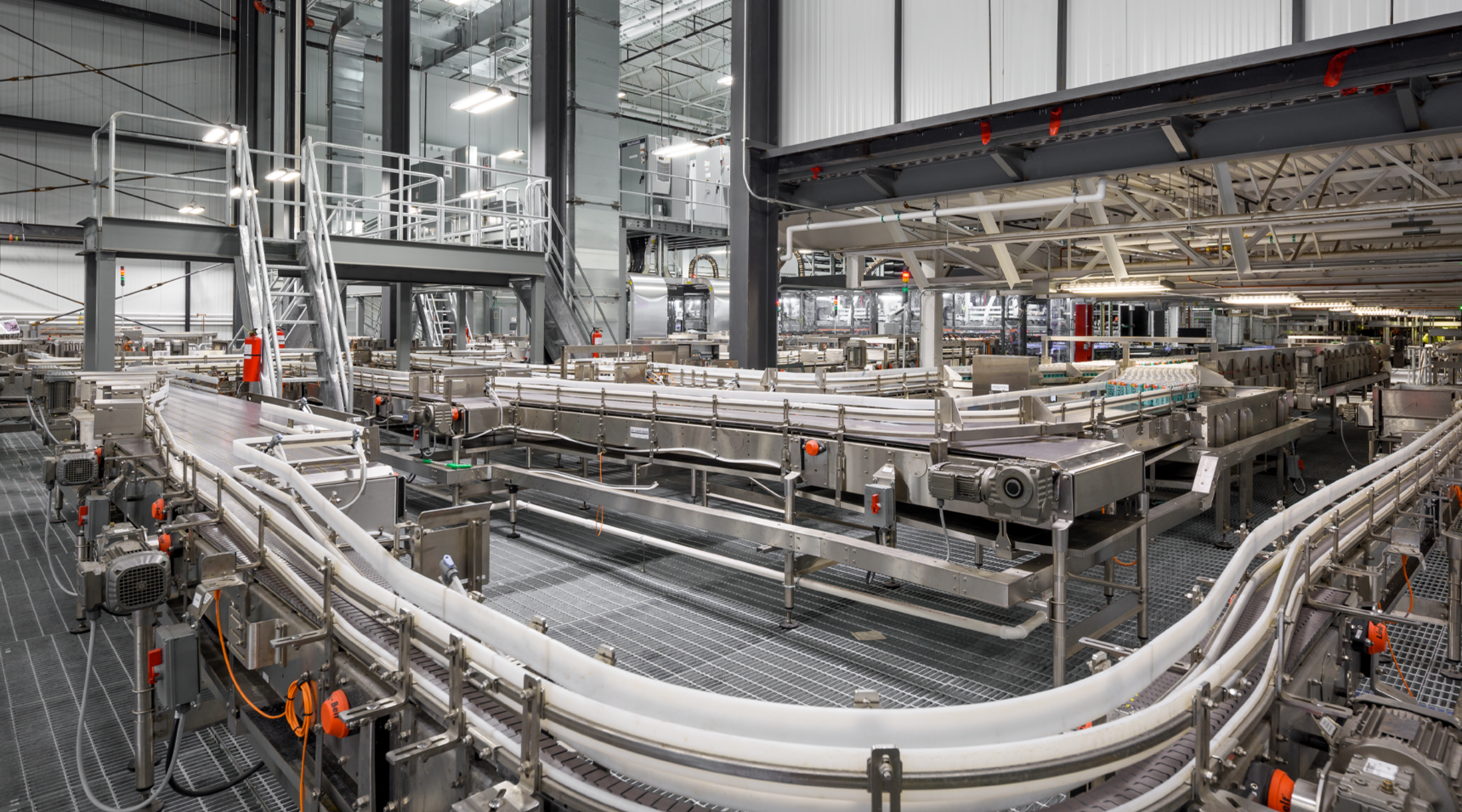

The Sam Adams Brewery project was a multi-phased expansion and renovation that touched all sides of the seven-acre site. This project included a 20,000 SF warehouse renovation, two-story, 9,000 SF addition for new depalletizing equipment, four new loading docks, future office space, 26-foot warehouse roof raising to accommodate new variety pack equipment (I-Collector), 15,000 SF additional and seven loading docs for new ASRA (Automated Storage and Retrieval System), 9,000-gallon storage tanks and containment unloading, bulk liquid product unloading bay, new welcome center and new entrance drive and site security, new parking lots for employees and visitors, and an 8,5000 SF Biomolecule purification ISEP (Ion Separation Exchange process) building with provisions for future keg line expansion.

Project InSite

This project InSite highlights the tight site and complexity of working in this downtown space while maintaining operations.

Danis has illustrated their attention to detail, quality, and safety throughout the project…Danis has met and exceeded Boston Beer Company’s safety program and worked closely with the on-site safety team. Danis was able to quickly adapt to schedule changes and material availability delays to minimize the impact to the overall project. In Addition, Danis has seen exceptionally accommodating when dealing with many unforeseen conditions and potential change orders…I recommend them and look forward to working with them again.

Robert Streuber

Senior Process Engineering Manager, Boston Beer Company